What tools do I need for my project?

There's no "One size fits all" approach, but there is a "One size fits most" approach.

A frequent question sent my way is “What tools do I need for my build?”

Now, there’s no single answer to this question, as the ideal list might vary from project to project. And of course there are some power and speciality tools which aren’t technically necessary, but can make for a lot less work.

That said, you can accomplish most of our builds (and most projects) pretty easily with 10 or so fundamental power and hand tools. Let’s get into it.

Tape Measure. Reliable measurements are pretty important, so do yourself a favor and buy one from a recognizable manufacturer.

Speed Square. You’ll use this 7" square to measure, to mark 90 degree cuts across a piece of wood, measure rafter angles, check if things are square, and as a guide for your circular saw.

Hammer. You’re going to want a medium-sized one for driving nails, removing nails, and for knocking pieces of lumber into place. (Use a sacrificial block when bashing your wood, so as not to bruise your build.)

Level. You’ll use this for checking if your foundation and floor joists are level. Or if a wall is standing straight up. Or if a door is plumb. You want to use the longest one possible (but a long one won’t always fit), so a kit with a few lengths is a good idea. A string level is useful for laying out footings or fence posts. A solid upgrade if you’re going to do a lot of builds, or work in trees, is a laser level. With lasers you get what you pay for in terms of brightness and usability. I like Bosch and they offer quite a few at different price points. I’m a fancy boy and use this one.

Impact driver and drill. I mention these at the same time because they’re often sold together as a discounted kit. One will do, but I recommend buying both. The drill excels at drilling, but can also drive screws. The impact driver is more efficient at driving screws, but can also drill. More importantly having two drivers means that if you’ve got a friend around and a bucket of framing screws, you can both get to work. Buy a small screwdriver bit kit and drill bit index to go along with your drivers. (Note that impact drivers are loud, but most manufacturers make a quiet version that costs a bit more. I use this one.)

(A note on framing screws: For smaller projects I prefer to use screws over nails. Specifically GRK screws. They drive better, rarely strip, never break, are reusable, and meet code. You can easily undo your work, which is very helpful if you’re inexperienced. And on a small project the total cost difference is pretty small.)

Saws. I recommend having two. You should have a handsaw for small jobs and delicate cuts where power tools won’t do (I prefer a Japanese pull saw), however the bulk of your cutting can be done a lot quicker with a circular saw. Just read up on some saw safety if you’re new to it. You can use your speed square as a guide to make square cuts and a rip guide to make ripping cuts down the length of wood. An upgrade if a lot of cutting is in your future is a miter saw. You can set this up as a station for anyone on the crew to make quick (and comparatively safe) square and angled cuts. Another upgrade would be a table saw if you need to rip a lot of wood along its length.

Tin snips. If you’re doing roofing, or doors and windows (think sheds and cabins), these cutters will allow you to cut and bend metal flashing.

Caulk gun. Not really applicable to furniture type projects, but if you’re erecting a building your doors and windows will need caulk. Buy a "no-drip" model.

Clamps. If you’re making furniture you definitely will need some clamps. For construction you can probably get away without them, however if you’re working solo you’ll find them indispensable as a second set of hands.

That’s pretty much it. Basic hand tools like wrenches and screwdriver and pryers are never a bad idea. And I could go into deep detail on other tools (and I have). Frankly I’ve got a ton of more niche recommendations, but for the sake of brevity, I’ll save that for another post.

A note on all the above brands and models:

These are just suggestions… models I’ve known and used, or stuff I feel comfortable suggesting as it’s reliably entry level and approachable in price.

As far as power tool brands go, all pro-grade stuff is pretty much the same and any allegiance generally speaks more to an investment in the batteries (or irrational brand identity) than it does a tool’s quality. DeWalt, Makita, Milwaukee… they’re all comparable. Ryobi is a good entry level product if you’re not ready for pro-grade prices.

Truthfully— especially if you’re just starting out— brands don’t matter all that much. Don’t overthink this. Buy something. Use it. Abuse it. If it’s cheap and it breaks, you’ll be better informed the next time you’re ready to invest a little more into the right tool.

Putting it into practice: Let’s breeze through a 10-step shed build.

The above basic toolbox will get most jobs done, and done quickly. To illustrate the point, let’s briefly run through a hypothetical project and see where they come into play. I’ll also mention a few bonus tools along the way. We’re going to build a super basic shed.

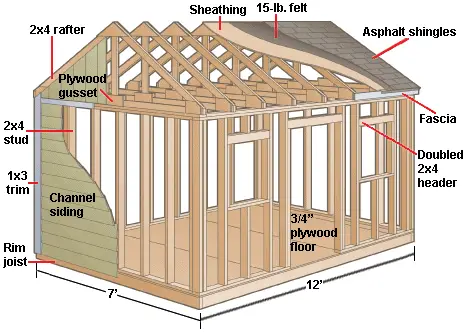

Something like this. You know... a shed.

You’ll need to lay out concrete paving stones or footings. A tape measure and some kind of level will get this done.

Next you start cutting all your lumber. Measure, mark with your speed square, then use that speed square to cut it with a circular saw. You’ll be doing this on the ground atop some blocks, so make (or buy) some sawhorses if you want to save your back.

You’ll start assembling your lumber using a hammer and nails, or an impact driver and screws. You’ll measure corner to corner to make sure it’s square and use a level to make sure it’s laying level, or standing straight up. First the floor joists, then the subfloor plywood. You’ll likely need to cut the plywood with a circular saw. Use your long level to mark a straight edge to cut along, or snap a chalk line to follow with your saw. Next, stand up your walls, which you’ll temporarily brace (to keep them square) with scrap wood and screws, or with your clamps.

Your roof rafters will go on and these might be held in place with hurricane tie hardware. You’ll use your driver on the screws for those. You can cut the angle of your rafters with a speed square, or your miter saw, or you can use a digital bevel gauge.

Plywood siding and trim and the roof sheathing can be done with a hammer and nails. Or with screws as well. They make trim-head screws for, well, trim, but trim nails are more traditionally used and if you want to drive trim head nails without bashing your nice wood, use nail sets.

Asphalt roof paper will help keep water out and can be tacked in place with a few roofing nails and your hammer. (You can use a stapler if you prefer, which is a good tool if you find yourself using Tyvek house wrap as a water barrier around the exterior of a cabin build.)

Roof flashing will get cut with tin snips and the corners folded, then nailed in place.

Your roofing material might be shingles- which can be installed with nails, or metal- which can be installed with your impact driver and screws.

For windows and doors you’ll need to drive some screws (and/or nails) and use a short level that can fit within the window frame. In following the manufacturer's instructions for the installation you’ll find there is a lot of shimming involved. You’ll want to tap those shims with your hammer. Caulk will also be involved in the process, so that’s where your caulk gun comes in.

A few pieces of trim around doors and windows and some caulk and paint where applicable and you’ve got a shed. Hopefully.